Genconnex Direct

Operating Tips

GENERAL MAINTENANCE TIPS

How Often should I change the oil

? With clean burning propane or natural gas, vs. gasoline, the oil doesn’t get as contaminated with

combustion products but we still recommend sticking with the OEM’s required oil change period as outlined in the Honda owner’s manual.

What maintenance should I do

? Please consult your OEM owner’s manual for scheduled maintenance including valve adjustment after 1000hrs.

In particular, you should keep your air cleaner element clean and lightly oiled. A dirty air cleaner will cause your generator to run rough or not at all.

Conversely, too much oil in your air cleaner element will also cause the engine to run rough or not at all. In addition, you should check hoses and

fittings for dirt, cracks and debris, and occasionally check the spark plug to make sure it is clean and properly gaped per the manual.

What

should

I

do

to

properly

store

my

Genconnex

®

generator

for

6

month

or

longer

?

If

your

generator

has

a

battery

make

sure

it

is

left

on

a

battery-maintainer

(trickle-charger).

As

of

2021,

all

7000’s

must

have

a

charged

battery

to

start

due

to

the

new

inclusion

of

a

secondary

fuel

solenoid

shut-off

inside.

It

will

no

allow

fuel

to

flow

without

12Vdc

from

a

charged

battery

or

equivalent.

Other

than

storing

your

generator

in-doors

in

a

relatively

dry

location,

to

keep

any

possible

rust

or

corrosion

from

forming

long-term,

there

is

really

nothing

more

you

need

to

do

to

the

fuel

system.

Please consult OEM manual for storing 1 year or more without use.

GENERAL OPERATING AND STORAGE TIPS

1.

Don’t let your generator tip over - this can lead to oil leaking out and/or saturating the oil filter element (chokes off air supply to unit).

2.

Don’t run your generator inside an enclosure or with its built-in enclosure panels off - cooling air must flow correctly inside and around unit.

3.

Let your unit cool down before putting the cover back on.

4.

Check your propane/natural gas hose for cracks and leaks with soapy water if you suspect a problem.

5.

Store your generator in a garage or in-doors to keep clean and ready to use but YOU MUST keep propane tanks outside.

©2012-2025

Please note we are not a Honda dealer. Honda is a registered trademark of Honda Motor Co.

EU7000is Gen-0-g & Gen-0-h made

between 2014 and 2019

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the oil stick in - just put it in then remove it and read the level. These do not ship with oil inside.

2.

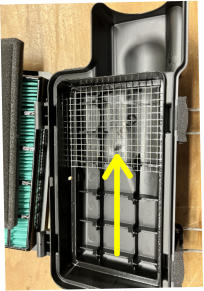

Check your air cleaner foam element to make sure it’s not pushed into the air cleaner cover air inlet and blocking the incoming air. See Picture 1

3.

Check that your air cleaner element is not flooded with oil. This can happen if your generator tips over. If it is, squeeze filter between paper

towels, then properly dispose of oily paper towels. (oily rags can spontaneously combust in garbage or in pile - hang until dry, then soak with

water and detergent before discarding)

4.

USE ONLY THE ORIGINAL MFG BATTERY. If you hear a “CLUNK” sound when you press the start button your battery is either no longer good

or just needs to be charged up. We recommend connecting a (1 Amp charge rate) battery tender to your generator and leaving it plugged in.

Check your battery voltage especially when below 40 deg F. If the battery voltage drops below approx. 10.4Vdc while cranking it may not turn

the engine over fast enough to get the vacuum actuated fuel system to allow fuel to flow. In extreme negative cold temperatures we

recommend adding a second battery (car battery) in parallel with the generator’s battery or jump starting with a car battery.

5.

Check that quick disconnect from hose to unit is fully seated and locked.

6.

Do not prime it unless you are trying to pull start it. In the event you have to pull start it, listen for slight “hissing” sound for 3 seconds before

starting when pulling up on purge ball knob located on top of lid inlet. This also lets you know if fuel is flowing to the generator.

7.

If using propane,

a.

Check that propane tank connection is fully screwed on and tight.

b.

Turn your propane tank off then back on slowly to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve may freeze up. Return tank to upright position and let it sit for a while without use to let

valve thaw and/or drain.

d.

Check that your propane tank isn’t empty, or near empty. If you shake the tank slightly you should hear the liquid propane slosh around a

bit.

8.

Change the spark plug. We STRONGLY recommend the Iridium/platinum NGK IFR6Q-G which comes factory gapped to 0.028” (as of

1/1/2024) for best starting and running particularly with natural gas in ECO on mode. A spark plug can have a damaged resister inside that

cannot be seen from the outside. The generator can sometimes still operate but it will run rough and not be able to get over approximately ½

power before dying as the load is increased.

9.

If your generator is connected to a remote start/stop device through the remote port on inside the front battery compartment, disconnect it

and re-install the Honda shorting plug back into the connector and try to start the generator. If the generator starts and runs fine then you

know the problem is with the remote starter.

POOR RUNNING TIPS

1.

Make sure the generator is not being run sitting flat on the ground or hard surface. There is a clear vent tube exiting out of the bottom of the

generator that must be open.

2.

Check that the battery strap is fastened down and not sucked into the air intake at the back of the battery compartment.

3.

For IMPROVED ECO MODE OPERATION - email us at sales@genconnex.net us for our free EU7000is upgrade kit. This is if your generator

runs fine on natural gas or propane when ECO MODE is off, but runs rough, occasionally sputters, or even occasionally turns off with ECO

mode on. It takes about 5 minutes to install and it solves this by re-routing a vent tube and new spark plug.

4.

If you cannot seem to get all of the available power out of your generator for powering your home or equipment:

a.

check that the voltage selection switch is in the correct position and make sure that you are not trying to get more than half of the

available power from one of the generator’s two power legs. This inverter generator that has two separate inverters that are either

placed in series for 240Vac or parallel for 120Vac operation. So, for instance if you are powering your home, make sure you do not have

4000Watts of load on one leg and 2000Watts on the other. Even rows of breakers in your main panel are on one leg and odd rows are on

the other. They make your main panel this way so a double breaker for 240Vac appliances is a double breaker that catches both legs

when installed. The 4 prong 30/30Amp outlet on the generators front panel has 1 Neutral prong, 1 Ground prong and two Hot prongs

(leg 1 and leg 2).

b.

make sure your fuel source has enough capacity for the given load. For instance, if you are trying to run 6000Watts from a 20lb BBQ

tank on a very cold day the tank will not have enough surface area to heat and vaporize the propane inside to match the rate the

generator is calling for. Get a bigger tank in this case or stand the tank 1ft behind the exhaust to blow heat at the tank.

5.

Check for shipping damage inside your generator. Open the side door and locate the top of the engine and look to see that the main brass pipe

and Tee fitting hanging down from the top of the generator is not touching the top of the engine. This can happen if the shipper had an

accident and another heavy item fell on top of the generator box causing the top metal lid to push down into the generator. This can be gently

fixed with a large flat blade screw driver by prying up between the top of the engine and the bottom of the heavy duty brass fitting to get an

approximate ½” of clearance.

6.

Change the spark plug. We STRONGLY recommend the Iridium/platinum NGK IFR6Q-G which comes factory gapped to 0.028” (as of

1/1/2024) for best starting and running particularly with natural gas in ECO on mode. A spark plug can have a damaged resister inside that

cannot be seen from the outside. The generator can sometimes still operate but it will run rough and not be able to get over approximately ½

power before dying as the load is increased.

7.

If your generator turns off (and you may get an “EOA” code and or oil light on your generator’s display):

a.

Check that you have the correct fuel orifice installed if your generator is hard to start and runs very rough then turns off. It is possible to

run from natural gas with the propane orifice installed, for instance, but it will idle very poorly, have very little power and will shut off after

the first 10min of running or so (once warmed up) then quickly on subsequent attempts to run. The number on the individual orifice

bags corresponds to the drill bit size used to make it. I.e. the #25 orifice is made with a #25 drill bit measuring 0.149 inches. Propane

has a higher energy density than natural gas so the holes size should be noticeably smaller than the natural gas orifices.

b.

Make sure you have the correct temperature orifice installed. There are 2 orifices available (free) for natural gas and 2 orifices available

for propane. High temp, normal and low temp. If you are running at or near 100deg F outside then you should install the high temp

orifice. If you are running at or near 0 deg F you should install the low temp orifice. Most installations should not need this but it

depends on your area. See the temperature recommendations on each orifice bag.

c.

Check that the upper air box is not cracked or has broken open if your generator will not start or run for very long. It is located behind the

left side door (when facing the outlets) and is to the upper right of the main air filter box. It is approximately soft-ball size, shaped like a

clam shell and has 4 small clips holding it together at the corners. This damage can possibly happen if you did not turn off the fuel as we

recommend first before turning the key off, or for off-grid and remote start units your plumber did not install per code a secondary lock-

off fuel solenoid. Note we now sell a lock-off solenoid that have gas quick disconnects on both ends so they can be easily connected to

the top inlet of the generator then connect to your hose. It’s powered from the generator’s un-used fuel pump wire harness so no

electrician or plumber may be needed. Click here for our Tech note on how it’s installed.

d.

If you are using your generator above 5,000ft you should install our free high-altitude orifice to correct for operation in a thinner

atmosphere

8.

We do not recommend running your generator inside of any other enclosure, building or facility without making sure to meet all town, state and

federal gas and fire codes. We also do not recommend this or changing the airflow into or out of the exhaust with exhaust extensions that are

not professionally designed and tested for this specific generator. Note all of these issues can be dangerous a person’s health, and cause poor

running (and it may be sporadic).

a.

If you are operating inside of a shed, garage or building that space can fill with carbon monoxide and most importantly become a death

trap. It may also re-route some of the exhaust back to the inlet and cause poor running.

b.

If the shed’s air inlet is too close to the exhaust port it can re-route some of the exhaust back to the inlet and cause poor running.

c.

Modifying the exhaust or removing it can change the back pressure and significantly change the engines performance or ability to run

EU2200i and EU2000i GENERATORS

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the oil stick in - just put it in then remove it and read the level.

2.

Check that the side run switch is set to on and that ECO mode is off for starting.

3.

Check that quick disconnect from hose to unit is fully seated and locked.

4.

If using propane,

a.

Check that propane tank connection is fully screwed on and tight.

b.

Turn your propane tank off then back on slowly to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve may freeze up. Return tank to upright position and let it sit for a while without use to let

valve thaw and/or drain.

d.

Check that your propane tank isn’t empty, or near empty. If you shake the tank slightly you should hear the liquid propane slosh around a

bit.

5.

Check that your air cleaner element is not flooded with oil. This can happen if your generator tips over. If it is, squeeze filter between paper

towels, then properly dispose of oily paper towels. (oily rags can spontaneously combust in garbage or in pile - hang until dry, then soak with

water and detergent before discarding)

6.

Pull the starter cord faster. Too slow a pull will not create enough vacuum in the system to allow the fuel to flow through the vacuum actuated

internal regulator.

Change the spark plug. A spark plug can have a damaged resister inside that cannot be seen from the outside. The generator can sometimes still

operate but it will run rough and not be able to get over approximately ½ power before dying as the load is increased.

POOR RUNNING TIPS

1.

If a EU2000i made roughly between 2017 and 2018 is running rough or turns off, change the rubber boot around the spark plug cap. Honda

put out a service bulletin mentioning that under certain conditions th boot can become conductive and partially or fully short out the spark

plug.

2.

Check for shipping damage inside your generator.

3.

For EU2200i generators made starting in 2021, make sure the pink vent tube just below the large side door is not clogged.

4.

If you are trying to run your EU2000i generator on natural gas, please contact us at sales@genconnex.net for our updated fuel injector and

natural gas orifice.

5.

Check that you have the correct fuel orifice installed if your generator is hard to start and runs very rough then turns off. It is possible to run

from natural gas with the propane orifice installed, for instance, but it will idle very poorly, have very little power and will shut off after the first

10min of running or so (once warmed up) then quickly on subsequent attempts to run. The number on the individual orifice bags corresponds

to the drill bit size used to make it. I.e. the #25 orifice is made with a #25 drill bit measuring 0.149 inches. Propane has a higher energy density

than natural gas so the holes size should be noticeably smaller than the natural gas orifices.

6.

If you are using your generator above 5,000ft you should install our free high-altitude orifice to correct for operation in a thinner atmosphere.

7.

Change the spark plug. A spark plug can have a damaged resister inside that cannot be seen from the outside. The generator can sometimes

still operate but it will run rough and not be able to get over approximately ½ power before dying as the load is increased.

8.

We do not recommend running your generator inside of any other enclosure, building or facility without making sure to meet all town, state and

federal gas and fire codes. We also do not recommend this or changing the airflow into or out of the exhaust with exhaust extensions that are

not professionally designed and tested for this specific generator. Note all of these issues can be dangerous a person’s health, and cause poor

running (and it may be sporadic).

a.

If you are operating inside of a shed, garage or building that space can fill with carbon monoxide and most importantly become a death

trap. It may also re-route some of the exhaust back to the inlet and cause poor running.

b.

If the shed’s air inlet is too close to the exhaust port it can re-route some of the exhaust back to the inlet and cause poor running.

c.

Modifying the exhaust or removing it can change the back pressure and significantly change the engines performance or ability to run.

9.

If your your generator still is running rough and lacks power or shuts off please email us for a free upgraded fuel injector module at

sales@genconnex.net.

EU7000is Gen-2 through Gen-3.3 made

between 2020 and 3/15/2023

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the oil stick in - just put it in then remove it and read the level. These do not ship with oil inside.

2.

Check your air cleaner foam element to make sure it’s not pushed into the air cleaner covers air inlet and blocking the incoming air. See Picture

1 above.

3.

Check that your air cleaner element is not flooded with oil. This can happen if your generator tips over. If it is, squeeze filter between paper

towels, then properly dispose of oily paper towels. (oily rags can spontaneously combust in garbage or in pile - hang until dry, then soak with

water and detergent before discarding)

4.

USE ONLY THE ORIGINAL MFG BATTERY. If you hear a “CLUNK” sound when you press the start button your battery is either no longer good

or just needs to be charged up. We recommend connecting a (1 Amp charge rate) battery tender to your generator and leaving it plugged in.

Check your battery voltage especially when below 40 deg F. If the battery voltage drops below approx. 10.4Vdc while cranking it may not turn

the engine over fast enough to get the vacuum actuated fuel system to allow fuel to flow. In extreme negative cold temperatures we

recommend adding a second battery (car battery) in parallel with the generator’s battery or jump starting with a car battery.

5.

Check that quick disconnect from hose to unit is fully seated and locked.

6.

Check that you hear a “click” at the top of the generator after you turn the key on and push the start button but before the starter cranks the

engine. This ‘click’ is the secondary fuel shut-off solenoid inside that is opening. No click means it is not opening and the generator will not

start. Please call us at 1-800-341-0792.

7.

If using propane,

a.

Check that propane tank connection is fully screwed on and tight.

b.

Turn your propane tank off then back on slowly to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve may freeze up. Return tank to upright position and let it sit for a while without use to let

valve thaw and/or drain.

d.

Check that your propane tank isn’t empty, or near empty. If you shake the tank slightly you should hear the liquid propane slosh around a

bit.

8.

Change the spark plug. We STRONGLY recommend the Iridium/platinum NGK IFR6Q-G which comes factory gapped to 0.028” (as of

1/1/2024) for best starting and running particularly with natural gas in ECO on mode. A spark plug can have a damaged resister inside that

cannot be seen from the outside. The generator can sometimes still operate but it will run rough and not be able to get over approximately ½

power before dying as the load is increased.

If your generator is connected to a remote start/stop device through the remote port on inside the front battery compartment, disconnect it and re-

install the Honda shorting plug back into the connector and try to start the generator. If the generator starts and runs fine then you know the

problem is with the remote starter.

POOR RUNNING TIPS

1.

Check that the battery strap is fastened down and not sucked into the air intake at the back of the battery compartment.

2.

Change the spark plug. We STRONGLY recommend the Iridium/platinum NGK IFR6Q-G which comes factory gapped to 0.028” (as of

1/1/2024) for best starting and running particularly with natural gas in ECO on mode. A spark plug can have a damaged resister inside that

cannot be seen from the outside. The generator can sometimes still operate but it will run rough and not be able to get over approximately ½

power before dying as the load is increased.

3.

If you cannot seem to get all of the available power out of your generator for powering your home or equipment

a.

check that the voltage selection switch is in the correct position and make sure that you are not trying to get more than half of the

available power from one of the generator’s two power legs. This inverter generator that has two separate inverters that are either

placed in series for 240Vac or parallel for 120Vac operation. So, for instance if you are powering your home, make sure you do not have

4000Watts of load on one leg and 2000Watts on the other. Even rows of breakers in your main panel are on one leg and odd rows are on

the other. They make your main panel this way so a double breaker for 240Vac appliances is a double breaker that catches both legs

when installed. The 4 prong 30/30Amp outlet on the generators front panel has 1 Neutral prong, 1 Ground prong and two Hot prongs

(leg 1 and leg 2).

b.

make sure your fuel source has enough capacity for the given load. For instance, if you are trying to run 6000Watts from a 20lb BBQ

tank on a very cold day the tank will not have enough surface area to heat and vaporize the propane inside to match the rate the

generator is calling for. Get a bigger tank in this case or stand the tank 1ft behind the exhaust to blow heat at the tank.

4.

If your generator turns off (and you may get an “EOA” code and or oil light on your generator’s display):

a.

Check that you have the correct fuel orifice installed if your generator is hard to start and runs very rough then turns off. It is possible to

run from natural gas with the propane orifice installed, for instance, but it will idle very poorly, have very little power and will shut off after

the first 10min of running or so (once warmed up) then quickly on subsequent attempts to run.

b.

Make sure you have the correct temperature orifice installed. There are 2 orifices available (free) for natural gas and 2 orifices available

for propane. High temp, all temp and low temp. If you are running at or near 100deg F outside then you should install the high temp

orifice. If you are running at or near 0 deg F you should install the low temp orifice. Most installations should not need this but it

depends on your area. See the temperature recommendations on each orifice bag.

c.

If you are using your generator above 5,000ft you should install our free high-altitude orifice to correct for operation in a thinner

atmosphere

5.

We do not recommend running your generator inside of any other enclosure, building or facility without making sure to meet all town, state and

federal gas and fire codes. We also do not recommend this or changing the airflow into or out of the exhaust with exhaust extensions that are

not professionally designed and tested for this specific generator. Note all of these issues can be dangerous a person’s health, and cause poor

running (and it may be sporadic).

a.

If you are operating inside of a shed, garage or building that space can fill with carbon monoxide and most importantly become a death

trap. It may also re-route some of the exhaust back to the inlet and cause poor running.

b.

If the shed’s air inlet is too close to the exhaust port it can re-route some of the exhaust back to the inlet and cause poor running.

c.

Modifying the exhaust or removing it can change the back pressure and significantly change the engines performance or ability to run

EU3000is GENERATORS

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the oil stick in - just put it in then remove it and read the level.

2.

If you have trouble starting in cold weather and have the computerized version with the yellow propane/natural gas selection rocker switch on

top, contact us support@genconnex.net to get your computer updated to B-3.5 revision firmware.

3.

Change the spark plug. We STRONGLY recommend the CHAMPION RC12YC gapped to 0.19-.023” (updated on 3/17/2025) for best starting

and running A spark plug can have a damaged resister inside that cannot be seen from the outside. The generator can sometimes still operate

but it will run rough and not be able to get over approximately ½ power before dying as the load is increased.

4.

Check that quick disconnect from hose to unit is fully seated and locked.

5.

If using propane,

a.

Check that propane tank connection is fully screwed on and tight.

b.

Turn your propane tank off then back on slowly to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve may freeze up. Return tank to upright position and let it sit for a while without use to let

valve thaw and/or drain.

d.

Check that your propane tank isn’t empty, or near empty. If you shake the tank slightly you should hear the liquid propane slosh around a

bit.

6.

Check that your air cleaner element is not flooded with oil. This can happen if your generator tips over. If it is, squeeze filter between paper

towels, then properly dispose of oily paper towels. (oily rags can spontaneously combust in garbage or in pile - hang until dry, then soak with

water and detergent before discarding)

Do not try to auto start stop a propane or natural gas Genconnex

®

modified EU3000is (ONLY the new EU3000is RS can do this). The EU3000is

configuration requires manual priming to start and we do not support any auto or remote starting or stopping. The RS version is designed to

self-prime.

POOR RUNNING TIPS

1.

Remove the front bezel (outlet side) and make sure the plastic vent tube from the main regulator is in the correct position and not clogged from

the insulation in the inside of the cover. See Pic 3

2.

Change the spark plug. We STRONGLY recommend the CHAMPION RC12YC gapped to 0.19-.023” (updated on 3/17/2025) for best starting

and running. A spark plug can have a damaged resister inside that cannot be seen from the outside. The generator can sometimes still operate

but it will run rough and not be able to get over approximately ½ power before dying as the load is increased.

3.

Check for shipping damage inside your generator.

4.

Check that you have the correct fuel orifice installed if your generator is hard to start and runs very rough then turns off. It is possible to run

from natural gas with the propane orifice installed, for instance, but it will idle very poorly, have very little power and will shut off after the first

10min of running or so (once warmed up) then quickly on subsequent attempts to run. The number on the individual orifice bags corresponds

to the drill bit size used to make it. I.e. the #25 orifice is made with a #25 drill bit measuring 0.149 inches. Propane has a higher energy density

than natural gas so the holes size should be noticeably smaller than the natural gas orifices.

5.

If you are using your generator above 5,000ft you should install our free high-altitude orifice to correct for operation in a thinner atmosphere

6.

We do not recommend running your generator inside of any other enclosure, building or facility without making sure to meet all town, state and

federal gas and fire codes. We also do not recommend this or changing the airflow into or out of the exhaust with exhaust extensions that are

not professionally designed and tested for this specific generator. Note all of these issues can be dangerous a person’s health, and cause poor

running (and it may be sporadic).

a.

If you are operating inside of a shed, garage or building that space can fill with carbon monoxide and most importantly become a death

trap. It may also re-route some of the exhaust back to the inlet and cause poor running.

b.

If the shed’s air inlet is too close to the exhaust port it can re-route some of the exhaust back to the inlet and cause poor running.

c.

Modifying the exhaust or removing it can change the back pressure and significantly change the engines performance or ability to run.

Trouble Shooting

GENERATOR WONT START OR RUNS VERY ROUGH

(All generators)

WONT START ON NATURAL GAS

1.

Check that you have correct fuel orifice installed if your generator uses orifices. We supply both propane and natural gas orifices. The orifice

with the largest hole is for Natural Gas. Actually remove the orifice in the generator and compare to make sure it was sent to you as requested

at the factory.

2.

If you generator has the top 1”primer ball do not pull up for more than 3 seconds or you can flood the engine with fuel. If you do this,

disconnect the hose from the generator and turn the engine over by hand a few times, or just wait 5 minutes for the prime charge to dissipate

out through the air cleaner. Re-connect and prime for 3 seconds again then pull or push button to start.

3.

Change the spark plug. For the EU700is we STRONGLY recommend the Iridium/platinum NGK IFR6Q-G which comes factory gaped to 0.028”

(as of 1/1/2024) for best starting and running particularly with natural gas in ECO on mode. A spark plug can have a damaged resister inside

that cannot be seen from the outside. The generator can sometimes still operate but it will run rough and not be able to get over approximately

½ power before dying as the load is increased.

4.

Check that your natural gas hose is as short as possible for the job. The longer the hose, the more air will be in it when you first connect it up so

it will take more time to pull start or key start as it will not run until the gas/air mixture works through. We recommend not using a hose longer

than 12 feet and not oversizing the diameter such that it’s bigger than needed. It could take 8-10 pulls to start with a 20 foot hose, where is

may still take 5-8 pulls the first time you connect up with a shorter 12foot hose.

WONT START ON PROPANE

1.

Check that you have correct fuel orifice installed. We supply both propane and natural gas orifices. The orifice with the smaller hole is for

Propane. Actually remove the orifice in the generator and compare to make sure it was sent to you as requested at the factory.

2.

If you generator has the top 1”primer ball do not pull up for more than 3 seconds or you can flood the engine with fuel. If you do this,

disconnect the hose from the generator and turn the engine over by hand a few times, or just wait 5 minutes for the prime charge to dissipate

out through the air cleaner. Re-connect and prime for 3 seconds again then pull or push button to start.

3.

DO NOT use our propane hose with/regulator in series with any other regulator. If you are connecting to a large storage tank (vs stand alone

BBQ tank) your propane dealer or installer will have either installed a two-stage regulator on the tank to get the propane to household ½” psi

pressure, or will have installed a primary stage regulator on the tank to reduce the pressure to 10-15psi then a second ‘final stage’ regulator on

your house to get the pressure further down to ½” psi as used by all appliances. DO NOT connect the generator to the mid point at 10-15 psi

or else you will have uncontrolled propane leaking through the generator which could combust causing serious injury or death. The hoses with

regulators we sell are all designed to operate ONLY from high tank pressure and CANNOT be used as a final stage regulator by attaching to the

intermediate pressure of 10-15psi. The generator may run but it will run very poorly and this could damage the generator.

RUNS VERY ROUGH ONCE STARTED

1.

Check the air cleaner element to make sure it’s not overly dirty or clogged. If your generator tipped over too far the engine’s oil can come out

through the crankcase vent and saturate the paper or foam air cleaner element. If this happens you will need to get a new air cleaner element.

Also check that the cleaning element is where it is supposed to be see picture 1.

Picture 1

EU7000is GENERATORS

(All made before 3/15/2023)

This is a solid billet-aluminum machined replacement for the Honda EU7000is upper air box

cover. It bolts directly to the EU7000is main carburetor studs with NO MORE CLIPS! It has

the same profile to seal to the original inner air box half with its gasket. This kit comes with

standoffs and bolts for mounting, a hose clamp for the crankcase breather tube, and an

anti-dive screen for installing in the lower air box under the Honda foam filter. This keeps

the foam filter from diving into the incoming air stream which causes overly rich operation.

This kit will still work even if your inner air box is missing a clip or landing.

Works with all version EU7000is

NO CLIPS EVER AGAIN!

Genconnex EU7000is aluminum replacement

upper air box cover, spark plug & screen

Picture 2

3 Most Common Solutions

Upper air box clips

landing areas can

break off if generator

backfires.

Foam air filter element

can push into incoming

air stream and cause

very rich operation and

backfiring.

Route through protected lined

hole with wire bundle

and cut to 2” on other side.

Or, remove tube completely.

EU7000is Gen-5 Tri-fuel and Bi-fuel with EFI

Starting 11/2023

(generators and kits)

POOR STARTING OR WONT START TIPS

1.

Confirm that the fuel selection switch is set for the fuel you are trying to use. For Bi-Fuel units make sure the switch is not in the middle “off”

position.

2.

A newly installed gas line will have air trapped in it that will prevent the generator from starting until the air is purged. The gas line installer

should purge the gas line before trying to start the generator.

3.

The Genconnex EFI controller learns how each generator starts and will make and store corrections. If you just installed a kit turn the generator

on 3-4 times without a load letting it run 30 seconds each time to let it collect data.

4.

Make note of what the LED’s do on the end of the EFI controller when starting. The EFI controller is located on the oil fill side door on Tri-fuel

units and up under the top on Bi-fuel units. There is a green “Power” LED, an LED for faulty O2 sensor, an LED for faulty barometric sensor

and an LED for faulty external temperature sensor. If any of these come on and stay on (not blinking on/off or on just for a moment) please

contact support. You will need a flashlight to see inside.

5.

Restarting a hot engine or one thats been running for a while too quickly after turning it off can lead to a poor re-start. We recommend waiting

5-10 min after turning it off if very hot or its been running for a long while before re-starting.

6.

Check the oil level. To do so, you do not screw the oil stick in - just put it in then remove it and read the level. These do not ship with oil inside.

7.

Check your air cleaner foam element to make sure it’s not pushed into the air cleaner covers air inlet and blocking the incoming air. See Picture

1 above.

8.

Check that your air cleaner element is not flooded with oil. This can happen if your generator tips over. If it is, squeeze filter between paper

towels, then properly dispose of oily paper towels. (oily rags can spontaneously combust in garbage or in pile - hang until dry, then soak with

water and detergent before discarding)

9.

USE ONLY THE ORIGINAL MFG BATTERY. If you hear a “CLUNK” sound when you press the start button your battery is either no longer good

or just needs to be charged up. We recommend connecting a (1 Amp charge rate) battery tender to your generator and leaving it plugged in.

Check your battery voltage especially when below 40 deg F. If the battery voltage drops below approx. 10.4Vdc while cranking it may not turn

the engine over fast enough to get the vacuum actuated fuel system to allow fuel to flow. In extreme negative cold temperatures we

recommend adding a second battery (car battery) in parallel with the generator’s battery or jump starting with a car battery.

10.

Check that quick disconnect from hose to unit is fully seated and locked.

11.

Check that you hear a “click” at the top of the generator after you turn the key on and push the start button but before the starter cranks the

engine. This ‘click’ is the secondary fuel shut-off solenoid inside that is opening. No click means it is not opening and the generator will not

start. Please email support.

12.

If using propane,

a.

Check that propane tank connection is fully screwed on and tight.

b.

Turn your propane tank off then back on slowly to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve may freeze up. Return tank to upright position and let it sit for a while without use to let

valve thaw and/or drain.

d.

Check that your propane tank isn’t empty, or near empty. If you shake the tank slightly you should hear the liquid propane slosh around a

bit.

13.

Change the spark plug. We STRONGLY recommend the Iridium/platinum NGK IFR6Q-G which comes factory gapped to 0.028” (as of

1/1/2024) for best starting and running particularly with natural gas in ECO on mode. A spark plug can have a damaged resister inside that

cannot be seen from the outside. The generator can sometimes still operate but it will run rough and not be able to get over approximately ½

power before dying as the load is increased.

14.

Check that the fuel valve that is placed just before the new outer airbox injector cover moves right after the start button is pressed. It should

move fully from closed to open then return to a mid position before the generator will start.

If your generator is connected to a remote start/stop device through the remote port on inside the front battery compartment, disconnect it and re-

install the Honda shorting plug back into the connector and try to start the generator. If the generator starts and runs fine then you know the

problem is with the remote starter.

POOR RUNNING TIPS

1.

For kits, make sure the long clear vent tube is fastened to the demand regulator port and exits out the bottom of the generator. Also make sure

the yellow wire is connected to the O2 sensor wire installed behind the lower air box.

2.

If the generator runs very rough for 10-12 seconds then corrects itself check that the O2 Sensor LED is not on (on EFI controller). The EFI

controller will reset to a default air/fuel ratio if the O2 sensor fails or becomes disconnected.

3.

Do NOT start the generator in ECO “ON” Mode. The computer starts the generator slightly rich to make sure it can start loaded up to 75% of

full power. This rich condition can affect the stability of the output voltage in ECO “on” mode until the EFI controller gets a good signal from the

O2 sensor. We recommend waiting 2 min before switching to ECO “on” mode after any startup.

4.

Check that the battery strap is fastened down and not sucked into the air intake at the back of the battery compartment.

5.

Change the spark plug. We STRONGLY recommend the Iridium/platinum NGK IFR6Q-G which comes factory gapped to 0.028” (as of

1/1/2024) for best starting and running particularly with natural gas in ECO on mode. A spark plug can have a damaged resister inside that

cannot be seen from the outside. The generator can sometimes still operate but it will run rough and not be able to get over approximately ½

power before dying as the load is increased.

6.

If you cannot seem to get all of the available power out of your generator for powering your home or equipment

a.

check that the voltage selection switch is in the correct position and make sure that you are not trying to get more than half of the

available power from one of the generator’s two power legs. This inverter generator that has two separate inverters that are either

placed in series for 240Vac or parallel for 120Vac operation. So, for instance if you are powering your home, make sure you do not have

4000Watts of load on one leg and 2000Watts on the other. Even rows of breakers in your main panel are on one leg and odd rows are on

the other. They make your main panel this way so a double breaker for 240Vac appliances is a double breaker that catches both legs

when installed. The 4 prong 30/30Amp outlet on the generators front panel has 1 Neutral prong, 1 Ground prong and two Hot prongs

(leg 1 and leg 2).

b.

make sure your fuel source has enough capacity for the given load. For instance, if you are trying to run 6000Watts from a 20lb BBQ

tank on a very cold day the tank will not have enough surface area to heat and vaporize the propane inside to match the rate the

generator is calling for. Get a bigger tank in this case or stand the tank 1ft behind the exhaust to blow heat at the tank.

7.

We do not recommend running your generator inside of any other enclosure, building or facility without making sure to meet all town, state and

federal gas and fire codes. We also do not recommend this or changing the airflow into or out of the exhaust with exhaust extensions that are

not professionally designed and tested for this specific generator. Note all of these issues can be dangerous a person’s health, and cause poor

running (and it may be sporadic).

a.

If you are operating inside of a shed, garage or building that space can fill with carbon monoxide and most importantly become a death

trap. It may also re-route some of the exhaust back to the inlet and cause poor running.

b.

If the shed’s air inlet is too close to the exhaust port it can re-route some of the exhaust back to the inlet and cause poor running.

c.

Modifying the exhaust or removing it can change the back pressure and significantly change the engines performance or ability to run

2) Runs too rich

3) Runs too lean

Change your spark plug to the NGK “IFR6Q-G”

Iridium/platinum plug that comes factory gapped to 0.028”

1) Runs rough in ECO “on” mode with natural gas

Upgraded

Upgraded

©2012-2025

Please note we are not a Honda dealer.

Honda is a registered trademark of Honda Motor Co.

GENERAL MAINTENANCE TIPS

How Often should I change the oil

? With clean

burning propane or natural gas, vs. gasoline, the oil

doesn’t get as contaminated with combustion products

but we still recommend sticking with the OEM’s required

oil change period as outlined in the Honda owner’s

manual.

What maintenance should I do

? Please consult your

OEM owner’s manual for scheduled maintenance

including valve adjustment after 1000hrs. In particular,

you should keep your air cleaner element clean and lightly

oiled. A dirty air cleaner will cause your generator to run

rough or not at all. Conversely, too much oil in your air

cleaner element will also cause the engine to run rough or

not at all. In addition, you should check hoses and fittings

for dirt, cracks and debris, and occasionally check the

spark plug to make sure it is clean and properly gaped per

the manual.

What

should

I

do

to

properly

store

my

Genconnex

®

generator

for

6

month

or

longer

?

If

your

generator

has

a

battery

make

sure

it

is

left

on

a

battery-maintainer

(trickle-charger).

As

of

2021,

all

7000’s

must

have

a

charged

battery

to

start

due

to

the

new

inclusion

of

a

secondary

fuel

solenoid

shut-off

inside.

It

will

no

allow

fuel

to

flow

without

12Vdc

from

a

charged

battery

or

equivalent.

Other

than

storing

your

generator

in-doors

in

a

relatively

dry

location,

to

keep

any

possible

rust

or

corrosion

from

forming

long-term,

there

is

really

nothing

more

you

need

to

do

to

the

fuel

system.

Please

consult

OEM

manual

for

storing

1

year

or

more

without

use.

GENERAL OPERATING AND STORAGE TIPS

1.

Don’t let your generator tip over - this can lead to oil

leaking out and/or saturating the oil filter element

(chokes off air supply to unit).

2.

Don’t run your generator inside an enclosure or

with its built-in enclosure panels off - cooling air

must flow correctly inside and around unit.

3.

Let your unit cool down before putting the cover

back on.

4.

Check your propane/natural gas hose for cracks

and leaks with soapy water if you suspect a

problem.

5.

Store your generator in a garage or in-doors to keep

clean and ready to use but YOU MUST keep

propane tanks outside.

EU7000is Gen-0-g & Gen-0-h

made

between 2014 and 2019

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the oil

stick in - just put it in then remove it and read the

level. These do not ship with oil inside.

2.

Check your air cleaner foam element to make sure it’s

not pushed into the air cleaner cover air inlet and

blocking the incoming air. See Picture 1

3.

Check that your air cleaner element is not flooded

with oil. This can happen if your generator tips over.

If it is, squeeze filter between paper towels, then

properly dispose of oily paper towels. (oily rags can

spontaneously combust in garbage or in pile - hang

until dry, then soak with water and detergent before

discarding)

4.

USE ONLY THE ORIGINAL MFG BATTERY. If you

hear a “CLUNK” sound when you press the start

button your battery is either no longer good or just

needs to be charged up. We recommend connecting

a (1 Amp charge rate) battery tender to your

generator and leaving it plugged in. Check your

battery voltage especially when below 40 deg F. If the

battery voltage drops below approx. 10.4Vdc while

cranking it may not turn the engine over fast enough

to get the vacuum actuated fuel system to allow fuel

to flow. In extreme negative cold temperatures we

recommend adding a second battery (car battery) in

parallel with the generator’s battery or jump starting

with a car battery.

5.

Check that quick disconnect from hose to unit is fully

seated and locked.

6.

Do not prime it unless you are trying to pull start it. In

the event you have to pull start it, listen for slight

“hissing” sound for 3 seconds before starting when

pulling up on purge ball knob located on top of lid

inlet. This also lets you know if fuel is flowing to the

generator.

7.

If using propane,

a.

Check that propane tank connection is fully

screwed on and tight.

b.

Turn your propane tank off then back on slowly

to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve

may freeze up. Return tank to upright position

and let it sit for a while without use to let valve

thaw and/or drain.

d.

Check that your propane tank isn’t empty, or

near empty. If you shake the tank slightly you

should hear the liquid propane slosh around a

bit.

8.

Change the spark plug. We STRONGLY recommend

the Iridium/platinum NGK IFR6Q-G which comes

factory gapped to 0.028” (as of 1/1/2024) for best

starting and running particularly with natural gas in

ECO on mode. A spark plug can have a damaged

resister inside that cannot be seen from the outside.

The generator can sometimes still operate but it will

run rough and not be able to get over approximately

½ power before dying as the load is increased.

9.

If your generator is connected to a remote start/stop

device through the remote port on inside the front

battery compartment, disconnect it and re-install the

Honda shorting plug back into the connector and try

to start the generator. If the generator starts and runs

fine then you know the problem is with the remote

starter.

POOR RUNNING TIPS

1.

Make sure the generator is not being run sitting flat

on the ground or hard surface. There is a clear vent

tube exiting out of the bottom of the generator that

must be open.

2.

Check that the battery strap is fastened down and not

sucked into the air intake at the back of the battery

compartment.

3.

For IMPROVED ECO MODE OPERATION - email us at

sales@genconnex.net us for our free EU7000is

upgrade kit. This is if your generator runs fine on

natural gas or propane when ECO MODE is off, but

runs rough, occasionally sputters, or even

occasionally turns off with ECO mode on. It takes

about 5 minutes to install and it solves this by re-

routing a vent tube and new spark plug.

4.

If you cannot seem to get all of the available power

out of your generator for powering your home or

equipment:

a.

check that the voltage selection switch is in the

correct position and make sure that you are not

trying to get more than half of the available

power from one of the generator’s two power

legs. This inverter generator that has two

separate inverters that are either placed in

series for 240Vac or parallel for 120Vac

operation. So, for instance if you are powering

your home, make sure you do not have

4000Watts of load on one leg and 2000Watts

on the other. Even rows of breakers in your

main panel are on one leg and odd rows are on

the other. They make your main panel this way

so a double breaker for 240Vac appliances is a

double breaker that catches both legs when

installed. The 4 prong 30/30Amp outlet on the

generators front panel has 1 Neutral prong, 1

Ground prong and two Hot prongs (leg 1 and

leg 2).

b.

make sure your fuel source has enough

capacity for the given load. For instance, if you

are trying to run 6000Watts from a 20lb BBQ

tank on a very cold day the tank will not have

enough surface area to heat and vaporize the

propane inside to match the rate the generator

is calling for. Get a bigger tank in this case or

stand the tank 1ft behind the exhaust to blow

heat at the tank.

5.

Check for shipping damage inside your generator.

Open the side door and locate the top of the engine

and look to see that the main brass pipe and Tee

fitting hanging down from the top of the generator is

not touching the top of the engine. This can happen

if the shipper had an accident and another heavy item

fell on top of the generator box causing the top metal

lid to push down into the generator. This can be

gently fixed with a large flat blade screw driver by

prying up between the top of the engine and the

bottom of the heavy duty brass fitting to get an

approximate ½” of clearance.

6.

Change the spark plug. We STRONGLY recommend

the Iridium/platinum NGK IFR6Q-G which comes

factory gapped to 0.028” (as of 1/1/2024) for best

starting and running particularly with natural gas in

ECO on mode. A spark plug can have a damaged

resister inside that cannot be seen from the outside.

The generator can sometimes still operate but it will

run rough and not be able to get over approximately

½ power before dying as the load is increased.

7.

If your generator turns off (and you may get an

“EOA” code and or oil light on your generator’s

display):

a.

Check that you have the correct fuel orifice

installed if your generator is hard to start and

runs very rough then turns off. It is possible to

run from natural gas with the propane orifice

installed, for instance, but it will idle very

poorly, have very little power and will shut off

after the first 10min of running or so (once

warmed up) then quickly on subsequent

attempts to run. The number on the individual

orifice bags corresponds to the drill bit size

used to make it. I.e. the #25 orifice is made

with a #25 drill bit measuring 0.149 inches.

Propane has a higher energy density than

natural gas so the holes size should be

noticeably smaller than the natural gas orifices.

b.

Make sure you have the correct temperature

orifice installed. There are 2 orifices available

(free) for natural gas and 2 orifices available for

propane. High temp, normal and low temp. If

you are running at or near 100deg F outside

then you should install the high temp orifice. If

you are running at or near 0 deg F you should

install the low temp orifice. Most installations

should not need this but it depends on your

area. See the temperature recommendations

on each orifice bag.

c.

Check that the upper air box is not cracked or

has broken open if your generator will not start

or run for very long. It is located behind the left

side door (when facing the outlets) and is to the

upper right of the main air filter box. It is

approximately soft-ball size, shaped like a clam

shell and has 4 small clips holding it together at

the corners. This damage can possibly happen

if you did not turn off the fuel as we

recommend first before turning the key off, or

for off-grid and remote start units your plumber

did not install per code a secondary lock-off

fuel solenoid. Note we now sell a lock-off

solenoid that have gas quick disconnects on

both ends so they can be easily connected to

the top inlet of the generator then connect to

your hose. It’s powered from the generator’s

un-used fuel pump wire harness so no

electrician or plumber may be needed. Click

here for our Tech note on how it’s installed.

d.

If you are using your generator above 5,000ft

you should install our free high-altitude orifice

to correct for operation in a thinner atmosphere

8.

We do not recommend running your generator inside

of any other enclosure, building or facility without

making sure to meet all town, state and federal gas

and fire codes. We also do not recommend this or

changing the airflow into or out of the exhaust with

exhaust extensions that are not professionally

designed and tested for this specific generator. Note

all of these issues can be dangerous a person’s

health, and cause poor running (and it may be

sporadic).

a.

If you are operating inside of a shed, garage or

building that space can fill with carbon

monoxide and most importantly become a

death trap. It may also re-route some of the

exhaust back to the inlet and cause poor

running.

b.

If the shed’s air inlet is too close to the exhaust

port it can re-route some of the exhaust back to

the inlet and cause poor running.

c.

Modifying the exhaust or removing it can

change the back pressure and significantly

change the engines performance or ability to

run

EU2200i and

EU2000i

GENERATORS

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the

oil stick in - just put it in then remove it and read the

level.

2.

Check that the side run switch is set to on and that

ECO mode is off for starting.

3.

Check that quick disconnect from hose to unit is

fully seated and locked.

4.

If using propane,

a.

Check that propane tank connection is fully

screwed on and tight.

b.

Turn your propane tank off then back on

slowly to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank

valve may freeze up. Return tank to upright

position and let it sit for a while without use

to let valve thaw and/or drain.

d.

Check that your propane tank isn’t empty, or

near empty. If you shake the tank slightly you

should hear the liquid propane slosh around

a bit.

5.

Check that your air cleaner element is not flooded

with oil. This can happen if your generator tips

over. If it is, squeeze filter between paper towels,

then properly dispose of oily paper towels. (oily

rags can spontaneously combust in garbage or in

pile - hang until dry, then soak with water and

detergent before discarding)

6.

Pull the starter cord faster. Too slow a pull will not

create enough vacuum in the system to allow the

fuel to flow through the vacuum actuated internal

regulator.

Change the spark plug. A spark plug can have a damaged

resister inside that cannot be seen from the outside.

The generator can sometimes still operate but it will

run rough and not be able to get over approximately

½ power before dying as the load is increased.

POOR RUNNING TIPS

1.

If a EU2000i made roughly between 2017 and 2018

is running rough or turns off, change the rubber

boot around the spark plug cap. Honda put out a

service bulletin mentioning that under certain

conditions th boot can become conductive and

partially or fully short out the spark plug.

2.

Check for shipping damage inside your generator.

3.

For EU2200i generators made starting in 2021,

make sure the pink vent tube just below the large

side door is not clogged.

4.

If you are trying to run your EU2000i generator on

natural gas, please contact us at

sales@genconnex.net for our updated fuel injector

and natural gas orifice.

5.

Check that you have the correct fuel orifice installed

if your generator is hard to start and runs very

rough then turns off. It is possible to run from

natural gas with the propane orifice installed, for

instance, but it will idle very poorly, have very little

power and will shut off after the first 10min of

running or so (once warmed up) then quickly on

subsequent attempts to run. The number on the

individual orifice bags corresponds to the drill bit

size used to make it. I.e. the #25 orifice is made

with a #25 drill bit measuring 0.149 inches.

Propane has a higher energy density than natural

gas so the holes size should be noticeably smaller

than the natural gas orifices.

6.

If you are using your generator above 5,000ft you

should install our free high-altitude orifice to correct

for operation in a thinner atmosphere.

7.

Change the spark plug. A spark plug can have a

damaged resister inside that cannot be seen from

the outside. The generator can sometimes still

operate but it will run rough and not be able to get

over approximately ½ power before dying as the

load is increased.

8.

We do not recommend running your generator

inside of any other enclosure, building or facility

without making sure to meet all town, state and

federal gas and fire codes. We also do not

recommend this or changing the airflow into or out

of the exhaust with exhaust extensions that are not

professionally designed and tested for this specific

generator. Note all of these issues can be

dangerous a person’s health, and cause poor

running (and it may be sporadic).

a.

If you are operating inside of a shed, garage

or building that space can fill with carbon

monoxide and most importantly become a

death trap. It may also re-route some of the

exhaust back to the inlet and cause poor

running.

b.

If the shed’s air inlet is too close to the

exhaust port it can re-route some of the

exhaust back to the inlet and cause poor

running.

c.

Modifying the exhaust or removing it can

change the back pressure and significantly

change the engines performance or ability to

run.

9.

If your your generator still is running rough and

lacks power or shuts off please email us for a free

upgraded fuel injector module at

sales@genconnex.net.

EU7000is Gen-2 through

Gen-3.3 made

between 2020 and

3/15/2023

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the oil

stick in - just put it in then remove it and read the

level. These do not ship with oil inside.

2.

Check your air cleaner foam element to make sure it’s

not pushed into the air cleaner covers air inlet and

blocking the incoming air. See Picture 1 above.

3.

Check that your air cleaner element is not flooded

with oil. This can happen if your generator tips over.

If it is, squeeze filter between paper towels, then

properly dispose of oily paper towels. (oily rags can

spontaneously combust in garbage or in pile - hang

until dry, then soak with water and detergent before

discarding)

4.

USE ONLY THE ORIGINAL MFG BATTERY. If you

hear a “CLUNK” sound when you press the start

button your battery is either no longer good or just

needs to be charged up. We recommend connecting

a (1 Amp charge rate) battery tender to your

generator and leaving it plugged in. Check your

battery voltage especially when below 40 deg F. If

the battery voltage drops below approx. 10.4Vdc

while cranking it may not turn the engine over fast

enough to get the vacuum actuated fuel system to

allow fuel to flow. In extreme negative cold

temperatures we recommend adding a second

battery (car battery) in parallel with the generator’s

battery or jump starting with a car battery.

5.

Check that quick disconnect from hose to unit is fully

seated and locked.

6.

Check that you hear a “click” at the top of the

generator after you turn the key on and push the start

button but before the starter cranks the engine. This

‘click’ is the secondary fuel shut-off solenoid inside

that is opening. No click means it is not opening and

the generator will not start. Please call us at 1-800-

341-0792.

7.

If using propane,

a.

Check that propane tank connection is fully

screwed on and tight.

b.

Turn your propane tank off then back on slowly

to check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve

may freeze up. Return tank to upright position

and let it sit for a while without use to let valve

thaw and/or drain.

d.

Check that your propane tank isn’t empty, or

near empty. If you shake the tank slightly you

should hear the liquid propane slosh around a

bit.

8.

Change the spark plug. We STRONGLY recommend

the Iridium/platinum NGK IFR6Q-G which comes

factory gapped to 0.028” (as of 1/1/2024) for best

starting and running particularly with natural gas in

ECO on mode. A spark plug can have a damaged

resister inside that cannot be seen from the outside.

The generator can sometimes still operate but it will

run rough and not be able to get over approximately

½ power before dying as the load is increased.

If your generator is connected to a remote start/stop device

through the remote port on inside the front battery

compartment, disconnect it and re-install the Honda

shorting plug back into the connector and try to start

the generator. If the generator starts and runs fine

then you know the problem is with the remote starter.

POOR RUNNING TIPS

1.

Check that the battery strap is fastened down and not

sucked into the air intake at the back of the battery

compartment.

2.

Change the spark plug. We STRONGLY recommend

the Iridium/platinum NGK IFR6Q-G which comes

factory gapped to 0.028” (as of 1/1/2024) for best

starting and running particularly with natural gas in

ECO on mode. A spark plug can have a damaged

resister inside that cannot be seen from the outside.

The generator can sometimes still operate but it will

run rough and not be able to get over approximately

½ power before dying as the load is increased.

3.

If you cannot seem to get all of the available power

out of your generator for powering your home or

equipment

a.

check that the voltage selection switch is in the

correct position and make sure that you are not

trying to get more than half of the available

power from one of the generator’s two power

legs. This inverter generator that has two

separate inverters that are either placed in

series for 240Vac or parallel for 120Vac

operation. So, for instance if you are powering

your home, make sure you do not have

4000Watts of load on one leg and 2000Watts

on the other. Even rows of breakers in your

main panel are on one leg and odd rows are on

the other. They make your main panel this way

so a double breaker for 240Vac appliances is a

double breaker that catches both legs when

installed. The 4 prong 30/30Amp outlet on the

generators front panel has 1 Neutral prong, 1

Ground prong and two Hot prongs (leg 1 and

leg 2).

b.

make sure your fuel source has enough

capacity for the given load. For instance, if you

are trying to run 6000Watts from a 20lb BBQ

tank on a very cold day the tank will not have

enough surface area to heat and vaporize the

propane inside to match the rate the generator

is calling for. Get a bigger tank in this case or

stand the tank 1ft behind the exhaust to blow

heat at the tank.

4.

If your generator turns off (and you may get an

“EOA” code and or oil light on your generator’s

display):

a.

Check that you have the correct fuel orifice

installed if your generator is hard to start and

runs very rough then turns off. It is possible to

run from natural gas with the propane orifice

installed, for instance, but it will idle very

poorly, have very little power and will shut off

after the first 10min of running or so (once

warmed up) then quickly on subsequent

attempts to run.

b.

Make sure you have the correct temperature

orifice installed. There are 2 orifices available

(free) for natural gas and 2 orifices available for

propane. High temp, all temp and low temp. If

you are running at or near 100deg F outside

then you should install the high temp orifice. If

you are running at or near 0 deg F you should

install the low temp orifice. Most installations

should not need this but it depends on your

area. See the temperature recommendations

on each orifice bag.

c.

If you are using your generator above 5,000ft

you should install our free high-altitude orifice

to correct for operation in a thinner

atmosphere

5.

We do not recommend running your generator inside

of any other enclosure, building or facility without

making sure to meet all town, state and federal gas

and fire codes. We also do not recommend this or

changing the airflow into or out of the exhaust with

exhaust extensions that are not professionally

designed and tested for this specific generator. Note

all of these issues can be dangerous a person’s

health, and cause poor running (and it may be

sporadic).

a.

If you are operating inside of a shed, garage or

building that space can fill with carbon

monoxide and most importantly become a

death trap. It may also re-route some of the

exhaust back to the inlet and cause poor

running.

b.

If the shed’s air inlet is too close to the exhaust

port it can re-route some of the exhaust back to

the inlet and cause poor running.

c.

Modifying the exhaust or removing it can

change the back pressure and significantly

change the engines performance or ability to

run

1.

EU3000is

GENERATORS

(generators and kits)

POOR STARTING TIPS

1.

Check the oil level. To do so, you do not screw the oil

stick in - just put it in then remove it and read the level.

2.

If you have trouble starting in cold weather and have the

computerized version with the yellow propane/natural

gas selection rocker switch on top, contact us

support@genconnex.net to get your computer updated

to B-3.5 revision firmware.

3.

Change the spark plug. We STRONGLY recommend the

CHAMPION RC12YC gapped to 0.19-.023” (updated on

3/17/2025) for best starting and running A spark plug

can have a damaged resister inside that cannot be seen

from the outside. The generator can sometimes still

operate but it will run rough and not be able to get over

approximately ½ power before dying as the load is

increased.

4.

Check that quick disconnect from hose to unit is fully

seated and locked.

5.

If using propane,

a.

Check that propane tank connection is fully

screwed on and tight.

b.

Turn your propane tank off then back on slowly to

check/reset tank internal valve.

c.

If your propane tank tipped over, the tank valve

may freeze up. Return tank to upright position

and let it sit for a while without use to let valve

thaw and/or drain.

d.

Check that your propane tank isn’t empty, or near

empty. If you shake the tank slightly you should

hear the liquid propane slosh around a bit.

6.

Check that your air cleaner element is not flooded with

oil. This can happen if your generator tips over. If it is,

squeeze filter between paper towels, then properly

dispose of oily paper towels. (oily rags can

spontaneously combust in garbage or in pile - hang until

dry, then soak with water and detergent before

discarding)

Do not try to auto start stop a propane or natural gas

Genconnex

®

modified EU3000is (ONLY the new

EU3000is RS can do this). The EU3000is configuration

requires manual priming to start and we do not support

any auto or remote starting or stopping. The RS version

is designed to self-prime.

POOR RUNNING TIPS

1.

Remove the front bezel (outlet side) and make sure the

plastic vent tube from the main regulator is in the

correct position and not clogged from the insulation in

the inside of the cover. See Pic 3

2.

Change the spark plug. We STRONGLY recommend the

CHAMPION RC12YC gapped to 0.19-.023” (updated on

3/17/2025) for best starting and running. A spark plug

can have a damaged resister inside that cannot be seen

from the outside. The generator can sometimes still

operate but it will run rough and not be able to get over

approximately ½ power before dying as the load is

increased.

3.

Check for shipping damage inside your generator.

4.

Check that you have the correct fuel orifice installed if

your generator is hard to start and runs very rough then

turns off. It is possible to run from natural gas with the

propane orifice installed, for instance, but it will idle very

poorly, have very little power and will shut off after the

first 10min of running or so (once warmed up) then

quickly on subsequent attempts to run. The number on

the individual orifice bags corresponds to the drill bit

size used to make it. I.e. the #25 orifice is made with a

#25 drill bit measuring 0.149 inches. Propane has a

higher energy density than natural gas so the holes size

should be noticeably smaller than the natural gas

orifices.

5.

If you are using your generator above 5,000ft you

should install our free high-altitude orifice to correct for

operation in a thinner atmosphere

6.

We do not recommend running your generator inside of

any other enclosure, building or facility without making

sure to meet all town, state and federal gas and fire

codes. We also do not recommend this or changing the

airflow into or out of the exhaust with exhaust

extensions that are not professionally designed and

tested for this specific generator. Note all of these

issues can be dangerous a person’s health, and cause

poor running (and it may be sporadic).

a.

If you are operating inside of a shed, garage or

building that space can fill with carbon monoxide

and most importantly become a death trap. It may

also re-route some of the exhaust back to the inlet

and cause poor running.

b.

If the shed’s air inlet is too close to the exhaust

port it can re-route some of the exhaust back to

the inlet and cause poor running.

c.

Modifying the exhaust or removing it can change

the back pressure and significantly change the

engines performance or ability to run.

Trouble Shooting

GENERATOR WONT START

OR RUNS VERY ROUGH

(All generators)

WONT START ON NATURAL GAS

1.

Check that you have correct fuel orifice installed if

your generator uses orifices. We supply both propane

and natural gas orifices. The orifice with the largest

hole is for Natural Gas. Actually remove the orifice in

the generator and compare to make sure it was sent to

you as requested at the factory.

2.

If you generator has the top 1”primer ball do not pull

up for more than 3 seconds or you can flood the

engine with fuel. If you do this, disconnect the hose

from the generator and turn the engine over by hand a

few times, or just wait 5 minutes for the prime charge

to dissipate out through the air cleaner. Re-connect

and prime for 3 seconds again then pull or push

button to start.

3.

Change the spark plug. For the EU700is we

STRONGLY recommend the Iridium/platinum NGK

IFR6Q-G which comes factory gaped to 0.028” (as of

1/1/2024) for best starting and running particularly

with natural gas in ECO on mode. A spark plug can

have a damaged resister inside that cannot be seen

from the outside. The generator can sometimes still

operate but it will run rough and not be able to get

over approximately ½ power before dying as the load

is increased.

4.